Keeping Legacy Equipment Productive

Older workshops across Europe still rely on proven machine tools because they are rigid, familiar to operators, and often perfectly matched to long-running jobs. This category includes lathes, milling machines, radial and column drilling machines, presses, shears, boring machines, and both surface and cylindrical grinding machines. Many of these units were built by Polish, German, Czech, Russian, Romanian, and Bulgarian manufacturers, so spare-part demand spans several design philosophies and documentation styles.

For legacy machines, the biggest advantage is that a well-maintained mechanical platform can run for decades, but the risk is downtime caused by one worn component. Typical needs include gears, clutches, feed screws, nuts, bearings, seals, belts, electrical contactors, pumps, and lubrication-system parts, plus complete assemblies like headstock elements or cross-slide components. The smartest approach is to combine original catalog references when available with precise measurements and wear checks, because older drawings may not reflect later factory revisions or workshop modifications.

Supporting Modernization and Mixed Fleets

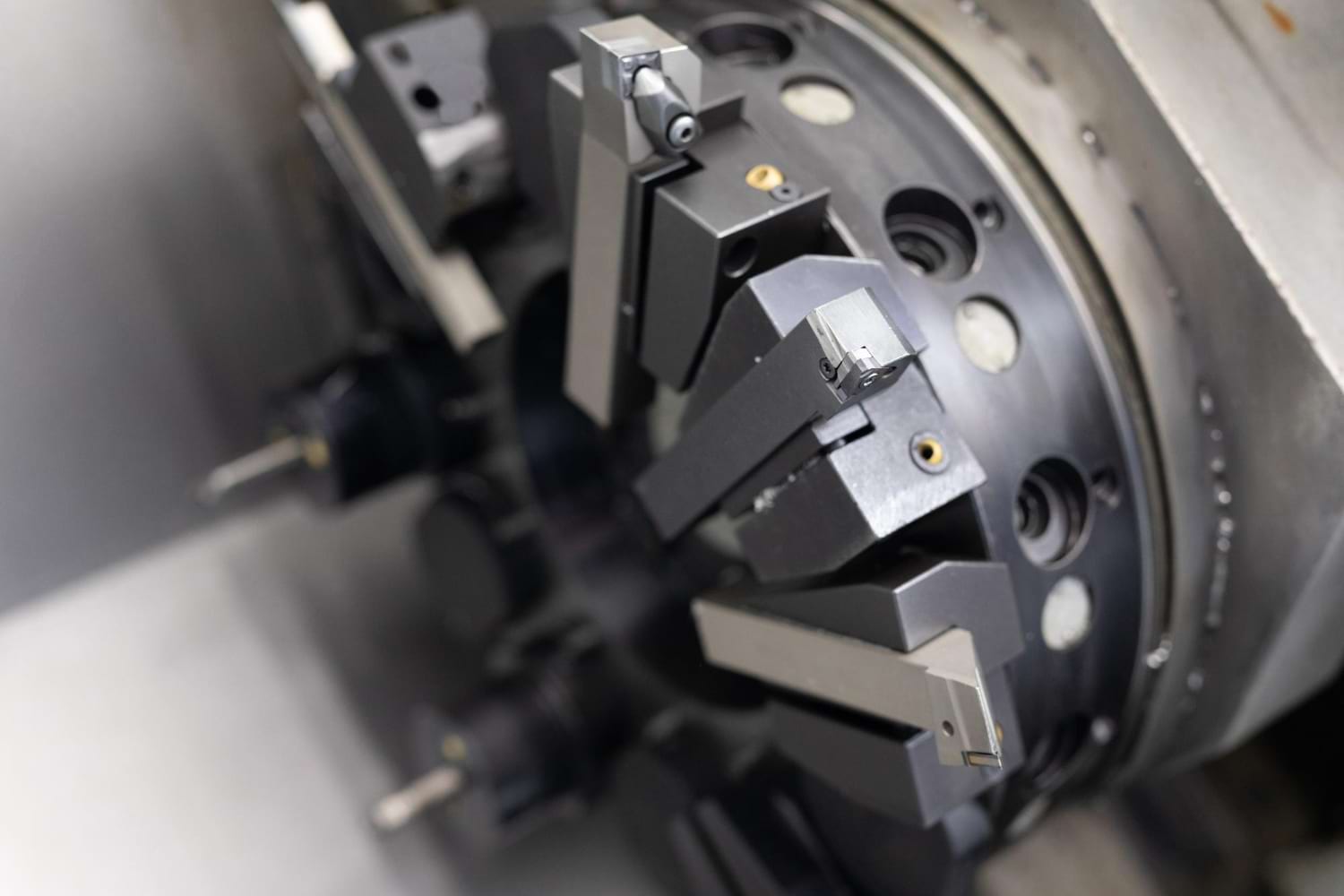

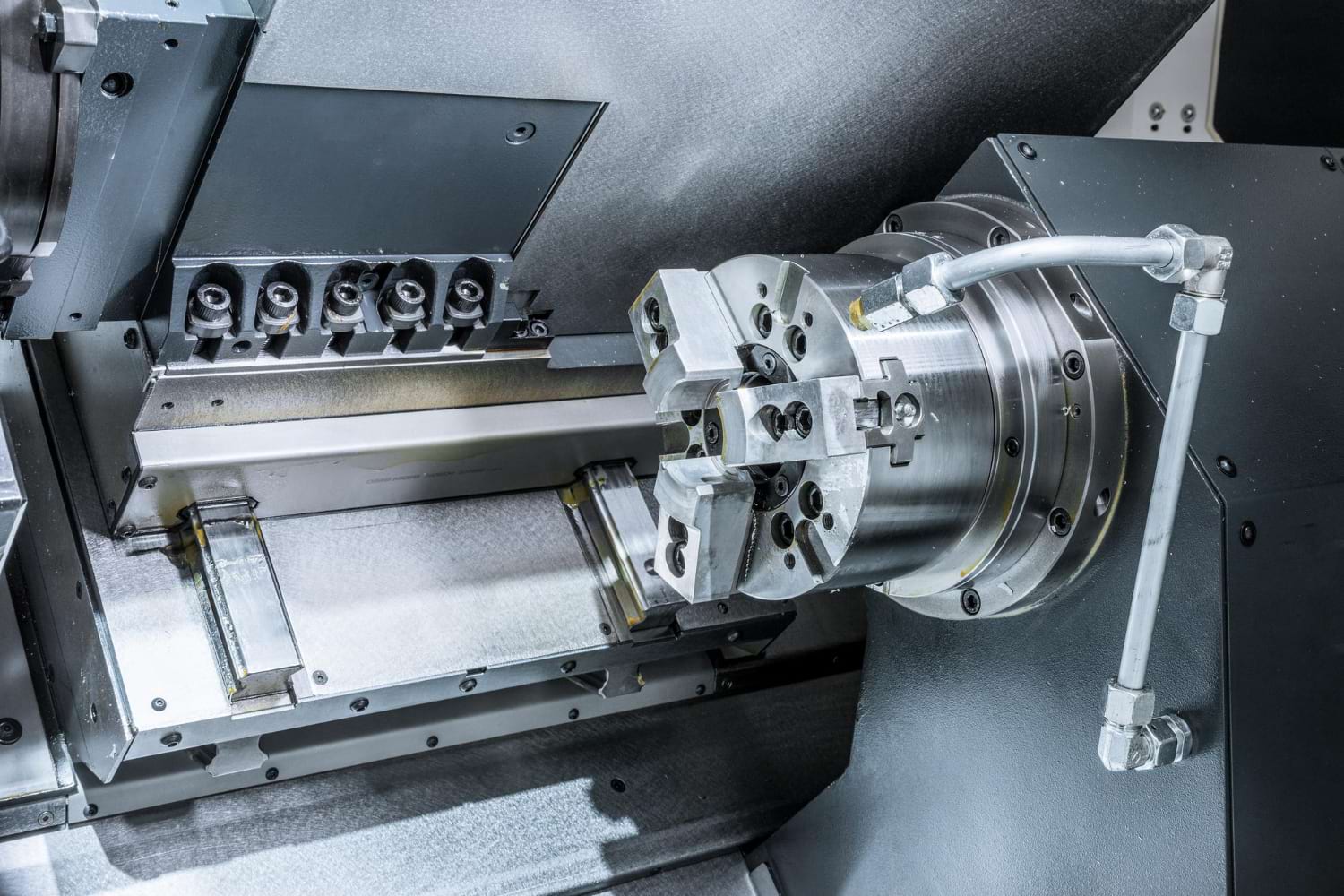

Modern machine tools introduce tighter tolerances, higher spindle speeds, and a heavier dependence on electronics, which changes what “spare parts” means in practice. Alongside mechanical items such as guideways, ball screws, and spindle bearings, customers often need sensors, encoders, drives, control panels, safety interlocks, hydraulic valves, and pneumatic modules that must match exact specifications. Even when a machine is not full CNC, upgrades and retrofits can add new compatibility constraints, so the right part is defined not only by dimensions but also by signal type, firmware requirements, and safety standards.

A reliable supply strategy starts with a complete machine identity set: nameplate data, serial numbers, retrofit history, and photo documentation of assemblies before disassembly, because that evidence prevents expensive ordering mistakes. When original parts are discontinued, machining spare parts from measured samples or reconstructed drawings can restore function while keeping the machine’s geometry and alignment intact. The best results come from pairing careful metrology with appropriate materials and heat treatment, then validating fit, backlash, and surface finish under real working loads.